Data Sheet - CPM S35VN

| Typical Composition | ||||

| C | Nb | Cr | Mo | V |

| 1.40 | 0.50 | 14.00 | 2.00 | 3.00 |

CPM S35VN is a martensitic stainless steel designed to offer improved toughness over CPM S30V. It is also easier to machine and polish than CPM S30V. Its chemistry has been rebalanced so that it forms some niobium carbides along with vanadium and chromium carbides. Substituting niobium carbides for some of the vanadium carbides makes CPM S35VN about 15-20% tougher than CPM S30V without any loss of wear resistance. CPM S35VN’s improved toughness gives it better resistance to edge chipping. Because both vanadium and niobium car bides are harder and more effective than chromium carbides in providing wear resistance, the CPM stainless blade steels offer improved edge retention over conventional high chromium steels such as 440C and D2.

The CPM process produces very homogeneous, high quality steel characterized by superior dimensional stability, grindability, and toughness compared to steels produced by conventional melting practices.

The typical applications include: Long-wearing specialty cutlery, plastic injection and extrusion feed screws and dies, non-return valve components, pelletizing equipment, and wear components for food and chemical processing.

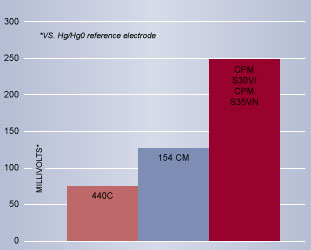

Corrosion Resistance

Average Pitting Potential measurements from Polarization Curves run in 5% NaCl (Sodium Chloride) Solution at Room Temperature: (Higher voltage pitting potential indicates better corrosion resistance.)

Toughness

| Grade | Impact Energy |

| CPM S35VN | 12.0 ft. lbs |

| CPM S30V | 10.0 ft. lbs |

| 154 CM | 2.5 ft. lbs |

| 440C | 2.5 ft. lbs |

Although the longitudinal toughness of all four grades is 25-28ft. lbs., the transverse toughness of the CPM grades is four times more than 440C and 154CM. CPM S35VN and CPM S30V are more resistant to chipping or breaking in applications with side loading and are better for bigger blades.

Edge Retention

| Grade | % |

| S35VN | 145- |

| S30V | 145 |

| 154 CM | 120 |

| 440C | 100 |

The CATRA test is considered a measure of relative wear resistance compared to 440C, in the table.

This data sheet is for informational purposes only. Alloy characteristics are subject to change due to chemical composition and/or processing. We do not certify the material’s suitability for specific applications.

Thermal Treatments

Forging: 2100°F (1150°C) Do not forge below 1750°F (950°C).

Annealing: Heat to 1650°F (900°C), hold 2 hours, slow cool no faster than 25°F (15°C) per hour to 1100°F (595°C), then furnace cool or cool in still air to room temperature.

Annealed Hardness: About BHN 255

Stress Relieving

Annealed Parts: Heat to 1100-1300°F (595-705°C), hold 2 hours, then furnace cool or cool in still air.

Hardened Parts: Heat to 25-50°F (15-30°C) below original tempering temperature, hold 2 hours, then furnace cool or cool in still air.

Straightening: Best done warm 400-800°F (200-425°C)

Hardening

Preheat: Heat to 1550-1600°F (845-870°C), Equalize.

Austenitize: 1900-2000°F (1035-1095°C), hold time at temperature 15-30 minutes.

Quench: Air or positive pressure quench (2 bar minimum) to below 125°F (50°C), or salt or interrupted oil quench to about 1000°F (540°C), then air cool to below 125°F (50°C).

Temper: Double temper at 400-750°F (200-400°C). Hold for 2 hours minimum each time. A freezing treatment may be used between the first and second tempers. Freezing treatments help to attain maximum hardenability and must always be followed by at least one temper.

NOTE: For optimum stress relieving, CPM S35VN may be tempered at 1000-1025°F (540-550°C). Tempering in this range may result in a slight decrease in corrosion resistance.

Size Change: +0.05 to +0.10% when fully martensitic. The presence of retained austenite may reduce the net growth. When tempering at 400-750°F (200-400°C), freezing treatments may be necessary to minimize retained austenite.

Recommended Heat Treatment:

Austenitize 1950°F (1065°C). Quench to below 125°F(50°C). Double temper at 600°F (315°C) 2 hrs. minimum each temper. Cool to hand warm between tempers. A freezing treatment may be added between tempers.

Aim hardness: 58-61 HRC.

| Carbide Type and Volume | ||||

| Vanadium | Niobium | Chromium | Total | |

| CPM S35VN | 3.0% | 0.5% | 10.5% | 14.0% |

| CPM S30V | 4.0% | 10.5% | 14.5% | |

| 440C | 0% | 12.0% | 12.0% | |

| 154 CM | 0% | 17.5% | 17.5% | |

| CPM S90V | 9.0% | 11.0% | 20.0% | |

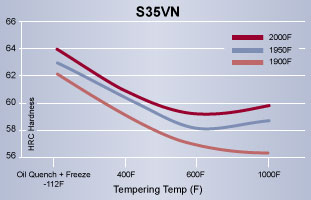

| Heat Treat Response-Hardness (HRC) | ||||||

| Austenitizing Temperature | ||||||

| 1900°F (1040°C) |

1950°F (1065°C) |

2000°F (1095°C) |

||||

| Tempering Temp. |

Oil | Oil & Freeze -112F |

Oil | Oil & Freeze -112F |

Oil | Oil & Freeze -112F |

| As Quenched | 60.5 | 62 | 62 | 63 | 63.5 | 64 |

| 400°F(200°C) | 57.5 | 59 | 57.5 | 60.5 | 59.5 | 61 |

| 600°F(315°C) | 57.5 | 57 | 59 | 58.5 | 59 | 59.5 |

| 1000°F(540°C) | 57 | 56.5 | 59.5 | 59 | 58.5 | 60 |

| *Results may vary with hardening and section size. Salt or oil quenching will give maximum response. Vacuum or atmosphere cooling may result in up to 1-2 HRC points lower. | ||||||

| Minimun Time at Aust. Temp. | 30 min. | 30 min. | 15 min. | |||

| Minimum Number of Tempers | 2 | 2 | 2 | |||

Machinability and Grindability

In the annealed condition, CPMS35VN is much easier to machine than CPM S90V and easier to machine than CPM S30V. Similar grinding equipment and practices used for high speed steels are recommended. “SG” type alumina wheels or CBN wheels have generally given the best performance with CPM steels.

Crucible Industries, Crucible Industries logo, CPM, 1V, 3V, 9V, 10V, S30V, S35VN, and S90V are registered trademarks of Crucible Industries LLC